Joining metals with glue has its own characteristics. First of all, this is the weak adhesion of adhesives to these materials; there is simply nowhere for the glue to be absorbed. Unless we have a special casting made of foamed metal or if the smooth surface of a metal product intended for gluing to another similar metal surface is not treated with a coarse abrasive. The coarser the abrasive, the better.

But metals have another feature - increased thermal conductivity. Therefore, all adhesives intended for joining metals with their help must be heat-resistant. Although this situation does not always save.

Selection Criteria

Metal glue is an alternative to classical welding.

The advantages include ease of use and no need to have special equipment. You can work at home without experience, relying only on the instructions for use.

In order for the connection of metal to metal or other material to be reliable, the means must be chosen taking into account future operating conditions. For example, the composition must be waterproof or heat resistant.

You should also pay attention to:

- for the period, conditions for hardening;

- maximum, minimum temperature at which the glue retains its properties;

- method of application to the surface - spot or continuous;

- type, form of glue (liquid, paste, one or two-component);

- the maximum load-bearing capacity of the seam, its elasticity.

The surfaces to be bonded are also taken into account. Universal mixtures will not be the best solution. It is necessary to use specific glue for specified purposes.

The increased viscosity of the composition expands the scope of application.

Sealants

When choosing an adhesive-sealant for metal, you need to focus on a number of its properties, including strength, elasticity and resistance to adverse environmental conditions. Silicone sealants are suitable for processing metal and plastic parts. This type is considered the most common because it is used in various types of work. The main brands in this case are “Universal Moment” and “Makroflex SX 101 Sanitary”.

Silicone can withstand exposure to ultraviolet radiation, temperature changes and precipitation. The only drawback is the impossibility of painting the seam in the desired color. Therefore, silicone glue can now be purchased in the desired shade that will suit the selected type of surface.

There are acidic and neutral types. The latter is applicable for working with metal surfaces. It is used to process drainpipes, ventilation and sewer connections. Heat-resistant types are used for hot water pipes, chimneys and radiators.

How to remove adhesive sealant?

This type of glue is removed mechanically, that is, cut off with a knife or spatula. You can purchase chemical compounds to soften the seam that can make the glue soft and remove even a thick layer of it.

Types of adhesives for metal

The most popular are epoxy adhesives, which come in one-component and two-component types.

- One-component ones are immediately ready for application.

- Two-component requires dilution before use. The resin is mixed with a hardener and applied to the surface.

Epoxy comes in liquid or paste form.

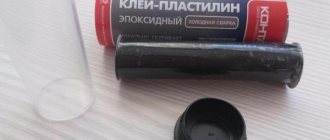

The second option resembles a block of plasticine, which is kneaded with your fingers and applied to metal or other base.

Depending on the speed of hardening, adhesives can be slow or fast.

An example of an epoxy mixture is Poxipol. Available in two tubes.

There are adhesives based on acetone and plastic. They harden due to the evaporation of the solvent. Not suitable for surfaces that will become hot.

Cold welding on metal

Review of epoxy adhesives

Hot melt adhesive, produced in the form of rods, is actively used in needlework. They are tucked into a glue gun and melt under high temperature. By pressing the trigger, the molten rod is applied to the iron through the nozzle of the heat gun.

Improved bonding quality

All surfaces must be clean and free of oil, grease and dirt. At a minimum, wipe the surface with a clean, dry cloth or blow off the surface with clean air. Use special primers for metal PURACARE 6214 .

Wipe all surfaces with primer to improve adhesion. Do not use lacquer thinners, mineral spirits, or benzine as they may leave a film that can cause gluing problems. Do not use household cleaners. They often leave marks that cause gluing problems.

PURACARE 6214 Special adhesion primer to improve adhesion on metals

Stamps

Poxipol

The glue is heat-resistant, water-resistant, and quick-hardening. Withstands low temperatures, resistant to moisture, waterproof. Adheses well to many surfaces. It has a gray color, which makes it invisible on metal.

The Poxipol package contains two tubes - the main component and the hardener. Mix in a 1 to 1 ratio and immediately apply to the metal base.

After 10 minutes the layer becomes durable. After an hour, the part can be machined - drilled, cut, sawed. But, complete polymerization requires 24 hours.

Poxipol is inexpensive, but has disadvantages:

- does not connect thin bases end to end;

- Due to its thick form, it is applied only in a thick layer.

Weicon VA 110

The composition has officially confirmed environmental friendliness (NSF certification).

- The glue is moisture resistant;

- operating temperature -30 – +80 °C;

- because of the cyanoacrylate it contains, it is called superglue - polymerization from 20 to 50 s;

- maximum strength after 24 hours;

- shear strength – up to 20 N per mm2 after sandblasting;

- no color, completely transparent;

- in addition to metal, glues plastic, rubber, caoutchouc and others;

- Can be used for metal utensils that come into contact with food.

The composition is expensive: for a 12-gram tube you will have to pay a little more than 1 thousand rubles, while 60 g of the product costs more than 3 thousand.

Strong steel stick renewal composite 114 g

Has high adhesion and rapid polymerization (20 minutes). The basis is epoxy resins. The structure is plastic, easy to apply. The shape is a plasticine rod. Before application, knead with hands.

After polymerization, it is resistant to stress, chemicals, salts, alkalis, acids, and solvents.

Great for patching pipes. Difficult to access on the Russian market, not so cheap. It has disadvantages similar to Poxipol.

Weicon RK-1500

Two-component adhesive composition for metal. Connects iron, steel, aluminum, and other alloys. Strongly holds thin sheets of metal end to end.

- Also suitable for plastics and ceramics.

- The glue can be called high-temperature: it can be used from -50 to +130 °C, and overheating is allowed up to 180 °C for a short time.

- Tensile strength after drying up to 26 N per square meter. mm.

- 5 minutes after treatment, the adhesive joint reaches its initial strength.

- The activator can be added to one or both sides of the main component. This depends on the thickness of the applied layer - from 0.4 mm to 0.8 mm.

- The activator must be applied carefully. Due to the too liquid consistency, it may spread.

- It even glues substrates of different structures, the adhesion between which is minimal, for example, metal with glass, other smooth substrates.

EpoximaxX

It is an improved version of the classic epoxy EAF. The hardening time (3 hours), thermal resistance (120 °C) have changed, and operation in heated conditions has become possible. EpoximaxX does not change properties when moistened. Tensile strength is 60-80 MPa.

The consistency is liquid, so application with a brush is possible. Recommended for gluing large areas overlapping rather than end-to-end. It's inexpensive.

Bison Super Glue Gel

This is superglue for minor household repairs. It is universal and adheres to different materials. The consistency is similar to a gel, which makes it easier to use and prevents spreading.

- It hardens in one to two minutes, which allows you to adjust the position of parts after fastening and reduce the risk of finger gluing, as in the case of conventional superglue.

- By spreading it on the metal, small cracks are filled with glue. pores, which increases the reliability of the coupling.

- The tube contains only 3 g of substance, enough only for small jobs.

The best superglue for plastic

The most popular method for gluing broken parts or assembling miniature models is superglue. The name itself speaks of the extraordinary speed of gluing and high strength of the connection. Among the huge variety of small tubes, experts have identified several products.

4 Henkel Super Moment Maxi

Henkel Super Moment Maxi

Instant bonding of plastic and plastic is appreciated by professionals. Not every glue can cope with this task, but the Henkel Super Moment Maxi product is suitable for solving the most difficult problems. It not only sets quickly, but also firmly connects different materials. In addition to polymer parts, the composition can glue metal, cardboard, ceramics and porcelain. The manufacturer has made soft, convenient packaging and an elongated tube spout. This made it possible to apply glue accurately and economically, without the craftsman’s hands being in the solution. The cap is easy to remove, and when closed it prevents air from getting inside the tube.

Experts note the instant setting of superglue, reasonable price and convenient bottle. The product qualitatively combines a wide range of materials, which attracts the attention of professionals. The disadvantage of the product is that it is of Russian origin, which is why its quality is not always stable.

3 Superglue POWER

Superglue POWER

High-quality superglue SILA is sold on the domestic market at an affordable price. At the same time, the composition firmly glues plastic, plastic, porcelain, glass, leather and wood. Thanks to the convenient tube, the required amount of glue can be accurately applied to the surface of the part. This has a positive effect on consumption. Experts note that there is no spreading; the gel does not drip onto other objects or hands. The basis of the product is ethyl cyanoacrylate, to which thickeners are added. After drying, the adhesive seam becomes transparent, which is important when gluing white or colored materials. The strength of the connection during testing was 175 N.

Users speak flatteringly about the effectiveness of the glue, affordable price, and ease of use. The glue does not have a strong odor and sets within a few seconds. Among the disadvantages, consumers note the insufficient thickness of the gel, as well as the presence of a large number of fakes on the market.

2 Economy Express Universal

Economy Express Universal

Chinese superglue Econ Express Universal has instant action. It is easy to use, sets quickly, and is unpretentious in work. The composition is suitable for gluing plastic and plastic, metal and paper, rubber and porcelain. Experts note the high strength of the adhesive joint; it can withstand a load of 210 N. The use of glue is quite standard, the surface of the parts is cleaned and degreased, applied to one of the parts, and the compression time is 5-60 s.

Users note the low price of the composition, good quality and reliable seam. Even under the influence of water, the glued parts do not separate. Consumers also respond positively to the sealed cap, through which air does not penetrate inside. The disadvantages include a pungent odor, which can give you a headache when working in a small, unventilated room.

1 Permatex Super Glue

Permatex Super Glue

Superglue Permatex Super Glue with a gel-like consistency is characterized by high bonding strength to plastic. During comparative tests, experts from the magazine “Behind the Wheel” recognized it as the winner. The destruction of the adhesive seam occurs under a load of 245 N, which significantly exceeds the performance of competitors. It is also noted that the glue is convenient to use when it is necessary to glue thin parts. The product is recommended for gluing hard-to-reach and vertical surfaces. High bond strength is observed on non-porous plastics.

Users are satisfied with the adhesive strength, speed of setting and ease of use. The seam turns out transparent, and in addition to plastic and resin, you can work with metal, rubber and ceramics. The product is economical in consumption, per 6 sq. cm of surface, one drop of the composition is enough.

Heat-resistant adhesive type "300"

Withstands temperatures up to 1000 degrees. And the lower limit is 300 degrees. The components do not deteriorate and do not change properties even after prolonged exposure to temperatures. Used in ovens and other heating devices.

If materials differing in structure, for example, metal and brick, are glued together, then both of them must be thermally resistant.

For interior work, a composition with minimal toxicity is selected.

Some manufacturers add refractory clay or a reinforcement element to the composition of the products to increase the strength of the connection.

- A well-known brand is the Russian D-3142. Glues ceramic tiles to the metal base of furnace equipment. Withstands heat up to 850 °C for a long time.

- Moment Epoxylin. Produced by the German company Henkel. Epoxy is used as a basis. Bonds iron, ceramic and other fragile substrates.

Composition and properties

Epoxy adhesives from different manufacturers may contain different components, but the basic composition is always the same, it complies with GOST and the attached certificates. Two main substances in the composition are strictly required:

- epoxy resin itself;

- liquid or paste hardener.

Polyamines, carboxylic acids, and aminoamides are used as a curing composition. One-component adhesives always contain solvents (acetone, xylene, alcohols), which prevent the mass from hardening before contact with air and evaporation. The following can act as modifying additives and fillers for glue:

- synthetic rubber;

- formaldehyde resin;

- fiberglass;

- clay, chalk;

- aluminium oxide;

- vanadium, nickel, zinc powders;

- organosilicon resins.

The glue also includes plasticizers, which give it plasticity. Thanks to them, the mixture hardens and does not crumble and remains elastic. The percentage of the main mass and various fillers varies widely - from 5 to 50%.

All of the above binding components provide the epoxy adhesive with the desired properties:

- optimal density;

- seam strength;

- high curing speed;

- resistance to oils, gasoline, water, atmospheric factors;

- resistance to cracks and shrinkage.

It is also worth noting that glue does not conduct current - it is a dielectric, so it is often used to insulate electricity.

How to glue correctly

The metal surface is cleaned of traces of rust, stains, dirt, and dust. The use of solvents or gasoline is not recommended. Adhesion can be increased by pre-treatment with a primer.

Glue is being prepared. If it is two-component, both ingredients are mixed in the required proportions. It is applied to the iron, both bases are pressed against each other, placed under a press or clamped in a vice.

Stirring and applying epoxy is done with a spatula or plate. It is often included with the packaging.

There are gluing methods, depending on the quality of the seam that needs to be obtained.

- Static rigid bonding. It is used for structures that will not be subjected to large mechanical loads or expand (contract) with temperature changes.

- Deformation bonding. On the contrary, it is used to create an elastic connection on structures subject to regular loads. For example, stairs, car bodies, racks, signs and others. Suitable for fixing metals with different linear expansion coefficients when heated or cooled.

An epoxy agent is suitable for both methods.

If the part is located in conditions of high humidity or under water, the adhesive seam is covered with a layer of paint. Otherwise, it will absorb moisture and corrosion will begin to appear.