High category for explosion and fire hazard of premises in the workshop of an industrial enterprise or production, storage area in a public building; division into fire compartments implies the construction of barriers to the path of fire/smoke - walls, ceilings, partitions with fire-resistant doors, hatches in building openings.

Fire doors are the most common type of filling, but not always acceptable due to cramped conditions; location, for example, in the interfloor ceiling of an industrial building for servicing technological equipment or the upper floor of a residential building for communication with the attic.

In such situations/cases, the best option is to install a fire hatch that performs all the main functions of the door, but is more compact and fits into the dimensions of the installation site.

Design

Fire hatch design

It consists of several parts/elements. The first is the canvas:

On this topic ▼

Fire doors

Main types and modifications

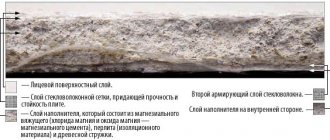

- It is the main element of fire hatches/doors. Most often, manufacturers choose steel sheets with a thickness of 0.8–2 mm as the material of manufacture, depending on the purpose of the upcoming installation sites and fire resistance. For example, for floor hatches, where the load can be significant, or for products with high strength, resistance to flame, heat, the maximum sheet thickness is selected. We should also not forget that, in addition to the functions of limiting/containing the spread of fire, such hatches/doors often protect premises from unauthorized entry; which means they must be durable and resistant to break-ins.

- In addition to metal, wooden elements can be partially used in the design of the hatch leaf, which allows fire protection of the wood. Looking ahead a little, it should be said that the product of any manufacturer must, in accordance with Federal Law of the Russian Federation No. 123-FZ, have a certificate of conformity obtained on the basis of fire tests, which gives customers/consumers a guarantee of compliance of the design, workmanship with the declared technical indicators of the fire hatch as a whole, used in it materials in particular.

- Filling the hatch space between the outer surfaces, frame, internal frame elements, and stiffeners is usually done with mineral wool in the form of slabs or rolls. For example, fire-retardant basalt material is often used for this, which is quite suitable for this purpose.

- The final finish of fire hatches is, as a rule, painted gray/white, as they are most often installed to serve technical floors/premises and various technological/engineering communications. Less commonly – finishing with decorative film or veneer for use in rooms where requirements are placed on the design of the finishing.

- The standard hatch panel does not have glazing, but it can be made to order.

- Most hatches have one panel; double-layer fireproof products are quite rarely made.

- The design of the fire hatch turns out to be quite weighty, which is not surprising, because the thickness of the canvas is 50–100 mm; and the mass is 1 square. m. depending on the materials, fire resistance ranges from 25 to 40 kg.

Box:

- It can be corner, with a platband on the outside. This is a universal and common type of PL box, allowing it to be mounted in almost any construction/technological opening. It should be noted that when installed in fire partitions/ceilings, this is most convenient.

- Less common are internal or end, as well as two-sided types of boxes.

- The PL box is made of steel angle, sheet, often galvanized, as well as a steel profile of square/rectangular section. The higher the resistance limit of a product, the greater the thickness of the metal used.

- A thermally active seal, often called a hot smoke tape, is fixed around the entire perimeter of the box; as well as a rubber profile that protects against the penetration of cold air/smoke. This compaction can be made in either one or two rows.

Hinges, handles, locks, closers:

On this topic ▼

Fire fittings

Description and requirements for it

- Hinges are standard for metal doors. There are no fire resistance requirements for them, because they are located inside the submarine structure.

- Locks and latching handles, installed depending on the need on one or both sides, have a different attitude - they must be made of fire-resistant steel; with a design that prevents jamming when the mechanism is overheated. To protect the lock during installation, fire-resistant linings are often used, which increases the reliability of unhindered opening/closing.

- Since most hatches, much more often fire doors, are used in a closed state, closers are not included in the standard equipment from the manufacturer. If, according to technological regulations, everyday/situational needs, the submarine must be in an open state, then it must be equipped with an automatic closing device in the event of a fire.

A rather rare type of design of a certified submarine is a combination of the use of fire-resistant glass and steel/aluminum alloys for the canvas frame and fire hatch box.

Selecting a submarine of a suitable design, size, appearance or ordering it to meet current requirements during construction, reconstruction or operation of a building is not particularly difficult. Dozens of manufacturers in Russia produce fireproof hatches and doors.

Useful tips

Before installing the structure, consider these simple tips for better results:

- Choose your material carefully. If it is wood, then it must be completely dry, free of knots and of the highest quality.

- It is necessary to carefully calculate the sizes of all elements. You cannot put an increased load on the hinges, so the ladder should be made so long that when unfolded it rests on the floor.

- To prevent accidental operation of the mechanism, install additional brackets at the bottom of the ladder. Otherwise, when opening the hatch, the structure may spontaneously unfold, injuring the user.

- Fasteners and fittings are one of the main elements of the entire product. The safety and durability of attic ladders depends on their quality, so select these items very carefully.

- For convenience, it is advisable to install one or more handrails so that a person of any age can easily climb up. This point must be considered at the design stage of the structure.

Handrails for attic stairsSource krovelnyj-mir.ru

Metal hatches for vertical openings

Such fire hatches are installed in fire walls/partitions separating shafts, elevator rooms, electrical panels, and ventilation chambers; engineering, technological galleries, tunnels and other communications of both buildings/structures of industrial enterprises and public and residential facilities.

The selected dimensions of submarines depend on whether it is necessary for service personnel to penetrate through them into adjacent rooms/communication shafts/niches or not. Although, according to industrial safety norms/rules, they are not always taken into account as evacuation routes/exits, but in practice, it is quite possible in many cases to use most of them to leave the premises in the event of an emergency.

A few tricks for more comfort

To make it convenient for you to climb into the attic, build the following supports around the hatch:

And the last point: if there is a special hinge on the hatch cover, it will be especially convenient to open it - just with the help of an extended handle. And you won't need to take a stool or use some kind of stand to reach it. Just make one end of such a handle in the form of a tetrahedron or hexagon.

Hatches to the attic

Fire hatch in the attic

According to SP 4.13130.2013, if the height of residential or public buildings does not exceed 15 m, then it is permissible to provide access to the attic or directly to the roof of the building from the staircase through a type 2 submarine. It must be at least 0.6 by 0.8 m, with a steel vertical ladder attached to the wall or floor/ceiling.

In real life, seeing fire hatches in the attic is a sure sign that this is happening on the 5th floor of a five-story residential building. True, often such a hatch has little in common with a submarine; it is made only of metal, if the house is new, or of wood covered with sheet iron, if it is a Khrushchev-era building.

Briefly about the main thing

An attic hatch inside the house allows you to quickly and without the need to go outside to enter the under-roof space. Its main functions are not only easy access to the attic, but also thermal protection, vapor barrier, fire barrier and small rodents. Such a design should be simple and easy to install and operate, durable, insulated if necessary, and consistent with the interior.

The main types of hatches differ in a number of parameters:

- The number of layers.

- Type of material.

- Thickness.

- Fire characteristics.

- Design.

When arranging a hatch for both a cold and a warm attic, it is necessary to take into account the type of ceiling - it can be reinforced concrete or wooden, as well as with an installed suspended or suspended ceiling. The nature of the work on cutting out the opening in them has its own characteristics. To ensure safety, the structure must have minimal fireproof properties. The insulation and finishing of the hatch must correspond to the characteristics of the building and the design style of the room.

Ratings 0

Metal floor hatches

Floor metal fire hatch

Such fire protection structures are installed in industrial and public buildings for access to basements, technical floors, corridors, cable tunnels, transport galleries, and overpasses. Basically, the most durable and fire-resistant type 1 submarines are installed, providing protection not lower than EI 60.

Short description

Those who plan to purchase a ready-made attic crawl space should know how to properly install this product. In addition, you can try to make a hatch yourself, but you need to adhere to some nuances. Absolutely all manholes perform a number of functions:

- blocking access to the house to various rodents and insects, which quite often live on the roof;

- high-quality thermal insulation;

- unhindered human access to the attic;

- excellent vapor barrier for living space;

- blocking smoke and fire from lower rooms in case of fire.

Each point is important in its own way. But fire safety needs to be addressed separately. The attic hole prevents the free spread of open fire, due to which poisonous gas cannot penetrate the house. A high-quality hatch is made of several insulating layers.

Experts recommend using different materials that have the ability to expand when exposed to high temperatures. Thanks to this, the product will not burn or break into pieces during a fire.

Good vapor barrier is also extremely important, since it is this property that allows you to retain valuable heat in the house. Otherwise, evaporation will escape through the cracks, causing moisture to be absorbed into all roofing insulation.

Type 2 hatches

Fire hatch type 2

The fire resistance limit of such a submarine is EI 30 - it must withstand fire/heat exposure for 30 minutes without loss of strength, integrity, without allowing flame, heat and smoke from the fire in the adjacent room or adjacent floor to enter the room.

Many manufacturers produce and use on site fire hatches of type 2 on the roof, which are somewhat different from other types of submarines:

- Its presence in the attics of residential and public buildings is regulated by SP 4.13130.2013.

- It must be no less than 0.6 by 0.8 m so that it is convenient to use for roof maintenance and work with external telecommunications equipment.

- A stationary staircase should lead to it.

- The hatch must be completely sealed and equipped with drainage to prevent freezing from blocking opening.

It is very rare to find such hatches in multi-storey residential buildings, but in modern public buildings they are used quite often.

Rating of the best hydraulic pipe benders for profile pipes

Hydraulic manual benders for profile pipes are in particular demand. Their prices are usually reasonable, and such machines are easier to handle than mechanical equipment. It is necessary to apply less force to form a bend.

APV-9 Professional

The Russian pipe bender is suitable for performing work both in the home workshop and on the road. The universal model supports three types of bending and interacts with both round and profile pipes. The device is equipped with thermally hardened prefabricated rollers, which allow you to independently set the dimensions of the groove; the elements are made of high-strength steel.

The hydraulic jack of the pipe bender has a lifting capacity of 10 tons and copes with workpieces of increased hardness. Allows you to work with both large and small pipes.

The average cost of a profile pipe bender APV-9 is 30,000 rubles

Metal Master APV-200

The compact but powerful hydraulic machine is capable of bending profile pipes with a maximum diameter of 60/40/2. The tool rollers are thermally hardened and have a high safety margin. There are a total of two clamping elements and one leading upper element. Thanks to the bearings, the rollers rotate easily, the side rollers can move in a horizontal plane, which provides a wide bending radius.

Important! The machine for profile pipes can be installed in a workshop, or you can take it with you to sites. The equipment fits easily into the trunk. The average cost of a hydraulic pipe bender APV-200 starts from 69,000 rubles

Metal Master TGA 40

The hydraulic profile pipe bender allows you to deform square and round pipes, as well as bend reinforcement and steel strips. Suitable also for the manufacture of railings, greenhouse elements and decorative parts. Suitable for both home and industrial use, the machine is used in construction, mechanical engineering and instrument making.

Demonstrates high resistance to operational loads. It is quite easy to operate, the workpiece is fed manually, and the hydraulic clamp ensures fast and accurate deformation. Suitable for processing profile pipes with a diameter of up to 40 mm.

You can buy a TGA 40 hydraulic machine from 20,000 rubles

Technical hatches

Technical fire hatches

Such fairly common fire-technical products are characterized by small sizes and are intended for installation in the enclosing structures of engineering/technological shafts, niches, chambers, boxes, and other communications to allow them to be inspected without service personnel entering inside.

Fire resistance type table

On this topic ▼

Determination of the fire resistance limit of building structures

It is given in Table 24 of the Federal Law of the Russian Federation No. 123-FZ, many SPs relating to the fire resistance limits of buildings, ensuring the non-propagation of fire, safe evacuation, and indicates that submarines can be of three types with minimum fire resistance limits:

- 1 – EI 60;

- 2 – EI 30;

- 3 – EI 15.

In practice, the fire resistance of a type 1 fire hatch is much greater if, for example, it is to be installed in a fire wall. Such designs are made only to order and can be up to EI 120.

Table of fire resistance limits for filling openings in fire barriers

How to do it yourself?

Any construction work begins with drawings and careful measurements. The next step is choosing the installation location. The rules for the location of the attic hatch in wooden and concrete structures are different.

In a wooden house, an opening is made between the beams, in a concrete house - at the junction of the slabs.

Arranging an opening in a concrete house is more complicated and involves several stages:

- First, a diagram is drawn on the floor, in the place where the hatch is supposed to be located (it is important to take into account that the size of the opening must exceed the dimensions of the hatch by a distance of at least 5 cm).

- Through holes are drilled in the corners of the outlined square or rectangle using a hammer drill.

- Next, cuts are made along the intended perimeter using an angle grinder.

Installation Features

Depending on the type of installation, there are wall, ceiling (attic) and floor hatches. The installation of fire hatches of various types/types is almost the same, but there are some features:

- Installation of ceiling and floor fire hatches is only possible with hinges facing outward, so that it opens upward, and the box of such a submarine is angular.

- When installing an internal PL frame, as well as products with an external frame of another type, if the integrity of the edges of a construction/technological opening is damaged, it is necessary to seal the junction with fire-retardant plaster along the entire perimeter.

- PL and fire doors can be equipped with electromechanical locks with automated/manual control from a surveillance console or fire station.

Only employees of an enterprise/organization with a valid license from the Russian Ministry of Emergency Situations for this type of work have the right to carry out work on installing fire hatches.