The modern market offers countless adhesives of varying quality, price and application. Our task is to help you choose the appropriate quality adhesive that is suitable for your particular case.

In this review, we will look at epoxy adhesive B7000, which has proven itself in many areas, but most of all helps service center technicians repair mobile devices and other electronics. It not only firmly connects the parts, but also acts as a sealant.

Description of glue and methods of application

General characteristics.

B7000 adhesive sealant is made in China from epoxy resin, which after special processing takes on a transparent gel-like appearance.

The composition is universal for gluing glass, metal, plastic, wood, wires and other electrical elements. The setting time is 10–15 minutes, and you need to wait 24 hours for complete drying.

B7000 is sold in convenient tubes of various sizes from 15 to 110 ml. Due to the thin metal tip, it is convenient to apply a thin layer to small parts. In addition, the cap has a special rod that fits into the tip and tightly closes the tube so that the glue does not dry out.

Advantages.

Consumers love this glue for its convenience and ease of use. It is absolutely transparent, has a high level of adhesion for the stated materials, and is also extremely practical, since when heated to 80–100 °C it becomes plastic and can be easily removed from the part. Moreover, it is very easy to remove excess glue from the surface by simply rolling it with your finger.

Unlike many adhesives, as well as analogues of B7000 itself, it is non-toxic. It can also be easily removed from hands, compared to the same superglue.

Areas of use.

B7000 glue is applicable in many areas of life, but it has gained the greatest popularity in the following areas:

- Composition No. 1 for repairing touch screens of phones, tablets and other electronic devices due to the ability to re-stick parts and excellent adhesion of plastic, metal and glass.

- It is actively used in electronics, as it guarantees reliable bonding of metal, wires, and plastic; convenient when working with small elements; and also does not conduct electricity and ensures tightness.

- Often used in needlework for gluing rhinestones, stones and other elements.

- It is used in shoe repair due to its elasticity and water resistance.

Using glue for other purposes

In every home there will always be work that requires gluing surfaces. Since glass glue is also a sealant, the use of this product is not limited and will be useful in various cases. The fact that the product is absolutely non-toxic makes it possible to use it for minor repairs in the apartment, for example replacing small cracked glass in a window frame or kitchen cabinet door. After drying, a glazing bead or decorative strip is fixed on top.

Instructions for use and basic operating rules

Working with B7000 glue is in many ways similar to working with other compounds; below is a step-by-step action plan:

- The temperature required for operation is from 18 to 32 °C.

- The surfaces to be glued must first be cleaned of dust, old glue residues and other contaminants, and then degreased with acetone or medical alcohol.

- The glue is applied to a dry surface in a thin layer directly from the tube; for this purpose it has a thin metal tip.

On a note!

Before joining the surfaces, wait a few minutes for the material to begin to harden a little, and then press them firmly together. This is especially important when replacing the glass of smartphones and tablets to avoid smudges on the screen.

On a note!

The glue does not threaten contacts that conduct current, since it is a dielectric (non-conductor).

Rules for working with glue

When using this sealant, you need to know exactly how long it should dry. The main setting time for the connection is approximately six minutes, but complete hardening of the material will take a maximum of two days. In order to correctly and reliably fix the parts used, it is necessary to take into account some important points:

- be sure to read the instructions for use;

- It is reasonable to first test the effect of the glue on a small area;

- the composition should not have a temperature exceeding 35 degrees;

- before gluing, the surfaces must be degreased and covered with an even layer of glue;

- press down on the tube as you use it;

- If the composition gets on your skin, rinse it with running water;

- avoid contact with eyes;

- after the expiration date it is not recommended for use;

- When working with the composition, it is better to open the windows to avoid the pungent odor.

Watch the video to find out more:

Important! This substance must be stored out of the reach of small children! Recommended storage of the tube at temperatures ranging from 10 to 28 degrees.

B7000 for touchscreens

The composition is ideal for repairing touch screens; it is even often called glue for touch screens or touch screens.

It is transparent, easy to apply in a thin layer, excess is easy to remove, and most importantly, the part can be easily peeled off again if the composition is heated to the desired temperature (80–100 °C). Since screens often break, this property comes in handy.

When repairing touchscreens, it is important to apply a thin layer of glue and not connect the parts immediately so that the composition has time to set a little. Otherwise, smudges may appear on the screen.

Use in handicrafts

B7000 is also actively used by needlewomen who work with glass, metal, wood, and glue beads, rhinestones and various stones to products. In fact, it is suitable for gluing any fittings.

In needlework it is valued for the following properties:

- Reliable bonding.

- It does not harden instantly, so the work can always be corrected if your hand trembles.

- Excess is easily removed, there is no fear of damaging the product with glue.

- Convenient thin tip for applying to small items.

The B7000 is often used to create jewelry, toys, and products using the popular scrapbooking and kanzashi techniques.

Analogs

If for some reason you do not find B7000 glue on sale, compositions B6000, B5000, F6000, E6000, E8000, Y7000 and T7000 are suitable for similar repairs. They differ in the level of adhesion of various materials, reliability of gluing and hardening time.

B6000 is suitable for gluing glass, plastic, fabrics. The composition is transparent, waterproof, begins to harden immediately after application, and it takes only ten hours to dry completely. Resistant to vibrations and retains plasticity even after complete drying.

B5000 is mainly used for gluing touch screens; the principle of operation is similar to double-sided tape, but it glues better.

Description of glue

Brand B 7000 adhesive is produced in China and is a high-quality composition with useful properties and a long service life. The basis of its composition is epoxy resin. The substance itself has a gel-like consistency. The principle of operation of the glue is similar to the action of double-sided tape, however, the level of adhesion will be much higher, and dismantling and re-gluing will also be easier if you follow the instructions.

Glue B 7000 is suitable for working with the following materials according to the instructions:

The main advantage of the epoxy elastic composition is that the finished adhesive joint can be peeled off without the use of other substances without damaging the base. The glue is available in thick polyethylene tubes of various sizes with a metal tip, which allows you to apply the transparent mass with a thin snake.

Main characteristics and properties of the glue, according to the instructions:

- Creating an elastic, soft and elastic seam.

- Anti-vibration function available.

- Optimal degree of viscosity that prevents the glue from spreading.

- Ease of use and application.

- The glue dries quickly - it sets in 3-6 minutes, completely hardens in 1-2 days.

Important! The glue is very economical in consumption. A minimum package of 15 ml is enough to adhere 3 smartphone displays.

Instructions for use

All manufacturers provide detailed instructions for its use on the glue packaging.

When working with the material, you can be guided by the following scheme and method of application:

- It is first necessary to prepare the surfaces for gluing, clean them of residues of other materials, dust, and dirt, as written in the instructions. The surface must also be cleaned of stains, thoroughly degreased and dried.

- Once the surface is completely dry and ready for use, you can proceed to applying the glue according to the instructions.

- After applying the glue, you need to leave the parts for a few minutes to polymerize. 30 seconds is enough.

- Then carefully connect them, pressing moderately.

Advice! If you wait a certain period before gluing, you can avoid glue getting into unintended niches and unsightly smudges.

5. According to the instructions, the pressed surfaces must be left in a static position for a certain period, preferably 24 hours, as indicated in the instructions, and wait until the glue has completely dried. It is advisable to use the finished item or glued parts after 2 days to achieve the strongest possible connection.

Advice! If, when compressing parts, excess adhesive mass still appears on their surface, it can be immediately removed by simply rolling off the glue. Or you can use a cotton pad moistened with acetone for this. If places are difficult to reach with a cotton pad or fingers, you can use a toothpick or a needle for small crevices.

On video: Replacing the touchscreen. Glue B 7000.

Adhesive sealant Ya Xun Y-7000 50ml (medium viscosity), transparent, for gluing the display to the frame

provides its own guarantee for the products we sell.

Warranty period for components for mobile phones, PSP and PDAs

- Warranty for products sold by us is 14 days from the date of purchase/sending of spare parts

The warranty for all products is valid subject to following simple rules:

- The protective film has not been removed (displays, touch/protective glass, etc.)

- No signs of self-repair (traces of disassembly, soldering);

- No mechanical damage;

- Preservation of warranty stickers, seals and packaging in which the spare part was purchased;

- Availability of all documents confirming the fact of purchase (invoice and/or receipt);

- Transportation costs for delivery of guaranteed products to the point of sale are not included in the warranty obligations.

The warranty does not cover spare parts, tools and equipment that have failed (lost consumer quality) as a result of mechanical damage, moisture, heating, electromagnetic influence or any other external factors that are not the culprit. Cables and keyboard backings are accepted without traces of mechanical impact (dents, bends, etc.).

Three steps to exchange goods of poor quality:

- 1. Fill out a return application

- 2. Send the Return Form by email;

- 3. In any way convenient for you, transfer the goods for quality control. Wait for a response from the complaints department!

If a defect is detected:

- Record the defect in the product (in a photo or video, depending on the nature of the defect), as well as the absence of a similar defect on your device.

- Send a photo/video of the defect by email

Worth knowing:

- Almost all displays fail as a result of mechanical shock. Breakage of the display due to “broken itself” is not a basis for return;

- Parts, like all equipment, have their own service life. Most of the cables fail before this time due to improper installation. This is especially true for slider phones.

- All components undergo quality control.

Please note that our product is technically complex. The list of technically complex goods that can be replaced only if there is a significant defect is approved by Decree of the Government of the Russian Federation of May 13, 1997 N 575. Defective goods are replaced with similar ones. If the product is currently out of stock, the money will be refunded or exchanged for another product (at the customer's request).

Attention!

If upon receipt of the parcel you see obvious defects in the box, you need to open the parcel in front of an employee, if the goods are of poor quality, draw up a REPORT OF DAMAGE ON THE INVESTMENT on the spot.

What can be glued

The most common question for those who purchased such a composition for personal use is what can be glued with it. These include most different materials and porous surfaces. In particular, it is intended for connecting parts of various household appliances and electronics, and is used for minor repairs, in the creation of handicrafts, and jewelry.

Touchscreens

The most common application for this glue is touchscreen repair. This is a touch screen or display that is sensitive to the touch of styluses and fingers. They can be used both for the production of smartphones and in other industries, medicine, and payment terminals.

The essence of using glue to repair a touchscreen according to the instructions:

- Most Chinese phones have touch screens glued to the B 7000 compound, so removing them will be quite easy.

- To change the screen, the glass of the phone is preheated and lifted with a sharp auxiliary object. To replace and glue the screen, a thin layer of adhesive is applied to the new part.

- But before you completely change a part of the device, you need to apply a drop of glue in an inconspicuous area and check the reaction of the material.

Rhinestones

The adhesive, transparent in its composition, allows you to work with rhinestones and glue them to any materials, including the most delicate ones. Glue B 7000 is chosen for these purposes, preferring Superglue, since the latter significantly complicates the work and gets the materials dirty. Adhesive B 7000 can be easily removed if necessary by folding or using sharp objects.

The ready-to-use composition can be used according to the following scheme and instructions:

- Drops of glue are placed on the surfaces to be glued at the locations of the rhinestones. The droplet size should be minimal.

2. The rhinestones are lifted with a sharp tip, melted by a candle flame, and applied to a drop of glue.

Advice! You can use tweezers for these purposes, dip the edge of the rhinestones in glue and place them on the fabric. But this method is more complicated.

3. The glued materials must be left until completely hardened.

Description and application of B-7000 glue

B-7000 brand adhesive from the Zhanlida company is a universal material for gluing a huge number of compounds. Otherwise it is called “Chinese superglue,” but there is a significant difference in composition with regular superglue or Moment.

The product is made on the basis of epoxy resin - a liquid polymer that provides a reliable, elastic connection. The difference from superglue is that the seam created can be peeled off without the use of special compounds and without damaging the base. Works like double-sided tape, only much stronger. In appearance, the glue is a transparent mass that is applied to the base like a snake.

B-7000 is sold in tubes of different volumes - 25, 50, 60, 100 ml; glue with a volume of 110 ml has recently become available.

The description says that the main properties and characteristics of the material:

- softness and elasticity of the adhesive seam;

- anti-vibration functions;

- no spreading due to optimal viscosity;

- ease of work;

- rapid surface setting - 3 - 6 minutes (drying time - 24 - 48 hours);

- economical - a 15 ml bottle is enough to glue 3 smartphone displays.

Transparent adhesive B-7000 can be used as a sealant for gluing metal, plastic, wood, glass, and ceramics. The product will hold equally firmly on products made of neoprene, leather, bamboo, rubber, paper, cardboard, fabric, and stone. Can be used on porous surfaces. You can glue parts of computers, laptops, other equipment, and electronic components. The glue is used in minor repairs, crafts, jewelry making, and handicrafts.

The product has few downsides. You must strictly follow the advice on how to use glue and follow safety precautions. The epoxy in the composition - a substance containing solvents - emits toxic fumes. This occurs during polymerization when the product is heated. After drying, the glue is 100% safe for humans, but you must work with the composition in a respirator and gloves.

Touchscreens

The instructions say that the product is used to repair touchscreens. A touchscreen is a touch screen or display that responds to the touch of fingers, a stylus, a special pen, or a stick. In addition to phones and smartphones, touchscreens are used in medicine and industry; they are equipped with tablets, game consoles, and payment terminals. They are very convenient: they replace the keyboard, mouse, joystick, reducing the number of devices.

Touchscreens can break, just like any other piece of technology. This happens due to a fall, careless use, strong pressure, or other mechanical impact. To replace the screen, B-7000 glue or its analogues are widely used.

The specifics of using the product for repairing touchscreens are as follows:

- Most Chinese phones have screens glued to the B-7000, which will simplify the work of removing the module or touchscreen;

- To replace a damaged screen, you need to slightly warm up the glass of the phone and lift it with a sharp object;

- You cannot apply a large amount of the product; it is distributed in a thin layer;

- Before work, you need to apply a drop of glue to an inconspicuous area and evaluate the reaction of the material.

General instructions for using B-7000 are given below.

Rhinestones

The transparency and reliability of the product allows you to glue rhinestones to any fabric, even the most delicate. Suitable for attaching other decorations and laying out patterns.

You shouldn’t think about what you can replace the product with - B-7000 is better than superglue, because the latter greatly stains your fingers and gloves and causes them to stick together. A huge plus for needlewomen is the ability to remove excess material by simply rolling it into balls or removing it with a sharp object. This glue is even used in jewelry making workshops.

Features of using glue for rhinestones are as follows:

- apply tiny drops of the product along the contour of the design in the places where the rhinestones should be located;

- the size of the drop is such that it slightly protrudes beyond the edges of the individual element;

- You need to take the crystals with a slightly melted sharp tip of the candle, and then apply them to the glue;

- You can grab rhinestones with tweezers, dip them in glue, or apply them to fabric, but this method is technically more complicated.

Other goals

In every home there are products that can be glued with this material. Since glue serves as a sealant, it is used for renovations in the bathroom and kitchen. It is often used to seal cracked glass in a window or a mirror on a cabinet. If the defect is located in a corner, after the product has hardened, you can attach a wooden strip to the mirror.

Using glue B-7000 they work with products made from genuine leather:

- belts;

- belts;

- purses and purses;

- bags;

- hair clips and headbands.

In addition to repairing finished products by gluing, it is possible to make jewelry with your own hands. How long does it take for a leather item to dry? The process lasts 24 hours; it cannot be used before. During this period, you can make new jewelry blanks, if required. To give the leather part volume, it is preheated over a flame and then glued together. It is imperative to treat the gluing area with sandpaper to improve the adhesion of the composition.

Many needlewomen create beautiful flowers, jewelry from plastic and decorative clay. After cutting out the parts, they are degreased with acetone or another solvent. After applying glue, leave it to dry for at least 24 - 48 hours (depending on the area of the seam).

Glue analogues

Glue B 7000 has a huge number of analogues of adhesive compositions, including glue under the designations T, E, which are also produced in China, but have some differences in technical characteristics and instructions.

E-7000 and T-7000

The E 7000 type of glue has a narrow specialization; it is created exclusively for gluing jewelry, parts, accessories and rhinestones. Sold in tubes from 10 to 50 ml, it is a new generation adhesive, made on the basis of epoxy resin, and dries depending on the amount of composition applied. But at the same time, it has an excellent degree of adhesion to various materials, is transparent in composition and invisible on any fabric. You can work with it on substrates such as ceramics, glass, plastic, neoprene, metal, wool.

Application according to instructions:

- It is often used by nail technicians.

- At home, it can be used to repair shoes, appliances and electronics.

- Suitable for gluing various items for interior decoration.

Glue T7 000 serves as an excellent replacement for type B 7000. They have the same purpose, but they differ in color. Composition T 7000 is black and has similar instructions for use.

T-8000, E-8000 and B-8000

T 8000 sealant is also very similar in properties and characteristics to B 7000 glue. It is actively used for household purposes, but also has a main purpose - repairing touchscreens. It has the properties of double-sided tape, but with maximum strength. The substance is easily removed by rolling and preheating. It also has a similar setting and hardening period to composition B 7000, prescribed in the instructions.

Glue E 8000 differs in composition by the main component - it is acrylic, which makes the substance more viscous in contrast to glue B 7000. It will be more difficult to work with porous surfaces and materials, but it is more resistant to external factors. E 8000 is used for joining glass, metal, ceramic parts, brick and fiberglass products. Suitable for gluing vinyl, wood, rubber and leather, when heated to +100 ° C, the seam becomes very plastic and can be easily removed.

Note! On store shelves you can find a composition called B 8000, which is designed to work with parts of smartphones from the Apple brand. It does not corrode surfaces, is easily removed after heating with a hairdryer and is transparent. The main properties are absolutely similar to those of composition B 7000, as are its instructions.

E-6000 and B-6000

The variety marked “6000” is the previous generation of the 7000 and 8000 brands. E 6000 is suitable for both domestic and industrial use. Can be used according to the instructions for working with stone, plastic, metal, fittings, rhinestones, fabrics and wool. Often used by handmade craftsmen, it is available in convenient packaging, small volume. But hardening can last up to 3 days.

Crystal clear composition B 6000 is intended for repairing mobile phones, working with jewelry, and also crafts. It contains acetone, so the substance has a sharp, characteristic odor. It is made on the basis of epoxy resin, which gives the seam waterproof properties, makes it elastic and immune to vibrations.

Outdated glue B-5000

Now the B 5000 brand has already been discontinued and is almost impossible to find on store shelves. They were replaced by improved formulations with detailed instructions. The glue was intended for working with electronics, in particular, for gluing touchscreens to frames. The glue had a medium thickness, transparent consistency, was produced in 110 ml tubes, and required longer fixation - up to 20 minutes.

B-7000 - universal adhesive from China

Hi all. In today's review we will talk about universal glue from the Middle Kingdom - B-7000. I think every home has a tube, or even several tubes, of glue that allows you to stick something to something. I'm not an exception. At home I have a bottle of 505 superglue, which often only sticks fingers to things and is pretty much useless without baking soda. There is also a tube “Moment. Crystal" - gel. Suitable for almost everything, but if you need to tear off the glued part, then this can be a problem. To fill this niche, I have been using the B-7000 for a long time. True, I only got around to writing a review now. I bought this glue more than once, from different sellers. The last purchase was made in the store at the link above. The seller sent the parcel quite quickly, and it spent about 3 weeks on the way. The parcel was sent with a track that was tracked only in China. If you are interested, all events on the track can be viewed here.

The glue is supplied in plastic tubes of different volumes: 25, 50, 60 and 100 ml. There may be other dosages, but these are the most common. In order not to remember about the new order, I purchased a 110 ml tube.

The appearance of the tube is the same for any dosage and differs only in size. The tube is covered on all sides with inscriptions in English. To make sure the packaging is accurate, let’s weigh our tube of glue.

As you can see, the mass of the glue including the packaging is 111 grams. And here we need to take into account the fact that I have already used the glue, so we can say that they are packaged more or less accurately.

A big advantage of the tube design is the presence of a metal tube in its spout. The cap also has a built-in needle, which seals the tube when the tube is closed. Thanks to this not very tricky, but effective solution, the glue in the spout does not dry out. During the next opening there is no need to scrape, punch or dig out anything. Well, through such a tip it is convenient to apply glue to the surfaces to be glued in the required volume - the glue line is thin and neat. Nothing just pours out of a bucket.

The glue itself is transparent. In its composition, appearance and smell it resembles that very “Moment.” Crystal". In terms of fluidity, B-7000 is more of a gel than a liquid glue.

In principle, there is nothing more interesting to say about the appearance, which means we can move on to considering one of the areas of its application. But before that, I think it would be useful to dwell in more detail on the characteristics of the glue.

So, the main advantage of B-7000 is that after heating to about 80 degrees, it becomes soft, elastic and can be removed quite easily. Also, after drying, this glue creates an elastic “layer” that has anti-vibration characteristics due to its soft consistency. The layer of material is waterproof, so it can serve as a kind of waterproofing. It is these features that predetermined the main area of use of this glue - it is often used to replace screens and back panels in smartphones, tablets, and so on. But the B-7000 perfectly glues metal, plastic, glass, wood, electrical components, and, in principle, anything.

This can be confirmed by the fact that this particular tube came to me either damaged or defective. During the work, the glue began to flow out from the side opposite the spout :). Then the leaked glue dried, covering the damaged part and the problem resolved itself.

Now about the characteristics. The information was taken from the product page, but based on experience of use, I can say that everything is true:

— Appearance: Translucent gel-like substance; — Solid content: 30% -35%; — Setting time is about six minutes; — The glue completely hardens after 1-2 days (24-48 hours). — It is recommended to store at ambient temperatures from 10 to 28? WITH.

For a long time I had two identical smartphones on my shelf - iNew V3. True, their problems were different. One had a broken touchscreen (white), and the second had severely damaged housing and main board (black).

Finally got around to carrying out minor repairs. The simplest and most effective method was to transplant a working touchscreen from one body to another. I think there is no point in describing the process of disassembling phones. The most important thing here is to carefully dismantle the working touchscreen so that it can be used in the future. This is not a very difficult task, but it requires care and attention. So we take it apart, warm it up, and take it out.

Of course, you could try to attach the touchscreen to old tape, but since it was partially damaged during dismantling, I’m sure that you could forget about securely fixing the screen. And even the slightest drop of water that flowed under the panel could cause the death of the phone. So there was only one thing left - using glue. And the B-7000 fits perfectly here. Carefully apply it to the frame in the places we need. Due to its consistency, it does not spread at all. So if you do everything carefully, then you don’t have to worry about it leaking into places it shouldn’t.

We wait a minute and apply the touchscreen. We press. Let's hold it for a minute or two. To be safe, you can press it all down on top with a heavy book or wrap it with paper tape. We leave it overnight, and in the morning you can already use your smartphone. Although it is better to wait 24 hours. Let's check how everything is stuck:

Not bad at all. Near the power button you can see that a little glue has squeezed out, but fortunately it comes off quickly and leaves no traces behind. To do this, just rub your finger over it. A minute later, all the glue protruding out was removed, and in his hands was a working phone, assembled from two half-dead bodies.

To sum up everything that has been written here, I can say that over the entire period of use, B-7000 glue has proven itself exclusively on the positive side. That’s why I always have a tube of it on my shelf. Sometimes it is its characteristics (reliability of gluing, ultra-low hygroscopicity and elasticity when heated) that make it possible to glue together something that is either impossible, or impractical, or not reasonable to connect with another glue. And the price of $3 for 110 ml, it seems to me, is reasonable. The same “Moment” costs, if not more, then the same, and at the same time, in terms of its characteristics, it obviously does not surpass the B-7000.

That’s why I always have a tube of it on my shelf. Sometimes it is its characteristics (reliability of gluing, ultra-low hygroscopicity and elasticity when heated) that make it possible to glue together something that is either impossible, or impractical, or not reasonable to connect with another glue. And the price of $3 for 110 ml, it seems to me, is reasonable. The same “Moment” costs, if not more, then the same, and at the same time, in terms of its characteristics, it obviously does not surpass the B-7000.

That's all. Thank you for your attention and your time.

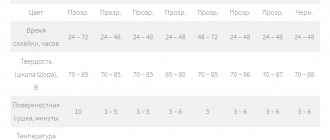

Comparison of adhesives

| E-6000 | B-6000 | T-8000 | E-8000 | B-8000 | B-7000 | E-7000 | T-7000 | |

| Viscosity | 3200 | 4500 | 3800 | 3800 | 3800 | 3500 | 3500 | 7000 |

| Color | Prozr. | Prozr. | Prozr. | Prozr. | Prozr. | Prozr. | Prozr. | Chern. |

| Gluing time, hours | 24 – 72 | 24 – 48 | 24 – 48 | 24 – 48 | 48 – 72 | 24 – 48 | 24 – 48 | 24 – 48 |

| Hardness (Shore scale), B | 70 – 85 | 70 – 85 | 70 – 85 | 65 – 80 | 70 – 85 | 70 – 86 | 70 – 87 | 70 – 88 |

| Surface drying, minutes | 10 | 3 – 5 | 3 – 5 | 3 – 6 | 5 | 3 – 6 | 3 – 6 | 3 – 6 |

| Storage temperature, degrees | 10 – 30 | 10 – 30 | 10 – 28 | 10 – 30 | 10 – 30 | 10 – 30 | 10 – 30 | 10 – 30 |

Rules for using glue B 7000 (2 videos)

In particular, b7000 glue is often chosen for repairing mobile devices, because it has proven itself well among professionals. This composition can truly connect parts with high quality, and also allows you to perform the functions of a sealant.

It is known that acquiring a wide variety of types of adhesives is not difficult. It’s easy to find adhesives at different prices, with different qualities and properties. However, each of them has an individual purpose and is applicable only in a certain situation.

For this reason, before using this composition, it is important to know the scope of its application, advantages and clear instructions for carrying out the work. Further in the article we will look at the advantages of using b 7000 glue for gluing touch screens.

Description of the substance

New generation Chinese adhesive B-7000 based on epoxy resin and with a gel consistency is used to repair damaged and replace new touch screens, as well as display modules on mobile communication devices. Transparent adhesive acts similarly to double-sided tape, but holds more firmly and can be easily removed for re-installation.

B-7000 adhesive creates an elastic film that has anti-vibration characteristics due to its soft consistency. The layer of material is waterproof, so it can serve as a kind of waterproofing. In addition to being used in the repair of mobile devices, it is used for gluing handicraft parts, ceramics, glass, metal, wood, natural and artificial leather. The connections between fabric, stone, polyvinyl chloride materials, nylon, and porous surfaces are strong and durable. Glued surfaces of plastic, rubber, paper, and bamboo serve reliably.

B7000 adhesive: benefits for touchscreens

Glue b 7000 is produced by Chinese manufacturers. One of the components is epoxy resin. Thanks to this substance, after pre-treatment the mixture becomes colorless and acquires the consistency of a gel.

It is known that such a composition is positioned as universal. However, they are often used to using it to restore the touchscreen.

The characteristics of the product allow for careful restoration of the smartphone without harming individual parts. This mixture is not toxic and does not harm the person who uses his gadget so often.

The sizing will be of guaranteed quality. There is no need to be afraid that after a certain time the composition will lose its fundamental properties. The mixture retains its adhesion characteristics over a long operational period.

It's no secret that gluing gadget parts involves small, painstaking work. In this regard, those who perform such repair work are likely to have glue on their hands. However, the adhesive mixture discussed in the article is so well thought out that wiping off its remnants from the skin will not be difficult.

So. the adhesive is presented in easy-to-use miniature tubes with a volume of 15 to 110 milliliters. Thanks to the thin metal tip, the mixture is easily and conveniently applied even to the smallest parts in a neat, even layer. Moreover, the cap itself is equipped with a rod, which is also inserted into the tip. The function of the device is to close the packaging as tightly as possible, which helps protect the product from drying out.

Other applications for b 7000 adhesive

B 7000 glue is most often used specifically for gluing touchscreens of various gadgets. However, it is suitable for use in other areas as well.

- Electronics. Thus, the product in question is widely used in electronics. The fact is that it has sufficient adhesion for gluing metal products, wires and plastics. It can also be used to glue the smallest parts of an object. Moreover, it does not allow electric current to pass through at all and guarantees complete tightness when gluing.

- This type of glue is also used in needlework. So, due to the fact that they are convenient for working with small parts, it is optimal for gluing rhinestones and other small elements.

- The B 7000 is often used by shoemakers in their work. This adhesive composition is elastic and does not allow moisture to pass through. Therefore, it is considered one of the most suitable compositions for sizing shoes.

Instructions for use of glue b7000

Adhesive b 7000 must be used only as prescribed in its instructions for use. So, first you need to provide it with optimal temperature conditions. It ranges from 18 to 32 °C.

Before you start gluing the surfaces, you will need to make sure that they are clean. From them you need to remove traces of previous glue, fingerprints, lint and other debris. After this, they need to be degreased using acetone or an alcohol solution. You need to apply the glue in an even layer directly from the tube. This is very easy to do, because the tube is equipped with a metal tip.

It is important that you will need to wait 3-5 minutes before starting to connect the surfaces. This way the material will begin to harden gently.

After this, both parts need to be pressed tightly against each other. It is extremely important to adhere to this rule when gluing new glass to a smartphone or tablet. Otherwise, not the most aesthetic smudges may occur.

If it happens that the adhesive ends up on other parts, it can be easily removed until it completely hardens. Remaining glue from the crevices can be removed with a needle or an ordinary toothpick. If the composition still has time to harden, the problem can be easily solved by heating the material. So, it needs to be heated to about 80 degrees, after which it will be softened and completely lose its adhesive properties.

The product in question does not pose a direct threat to contacts that conduct current. By its principle, it is a dielectric, so it does not conduct current. Are you interested in the question of how long does b7000 glue take to dry? It may take up to fifteen minutes for the parts to set firmly. Complete drying takes place within 24 hours.

Work technology

To ensure correct and reliable fixation of parts, you should be guided by important principles:

- Please read the instructions for use first;

- first test the ability of the glue on an invisible area;

- do not heat the glue to temperatures exceeding 35° C;

- press on the tube smoothly as the mass flows out;

- Remove any mixture that gets on your skin by rolling it up, wash your hands with soap and water;

- protect your eyes from getting glue;

- do not use a composition that has expired;

- Carry out gluing in a ventilated area to protect yourself from a pungent odor.

Important! Glue B-7000 is stored without loss of working properties at a temperature of 10-28 ° C, out of the reach of children's hands.

The procedure for using the composition is simple and follows the instructions on the packaging:

- Clean surfaces from old glue, dust and dirt.

- Degrease and dry parts.

- Apply the glue in an even layer, wait for it to dry lightly for about 30 seconds, so that the liquid mass does not penetrate into unnecessary voids under pressure.

- Connect the parts evenly, pressing lightly against each other, and fix in this position.

- Use of the bonded device is recommended after 48 hours.

- Excess glue can be easily removed by rolling it off the surface of the gadget with your fingers. For thorough cleaning, the easiest way is to use a cotton pad soaked in acetone. A needle or toothpick will help remove remaining glue from hard-to-reach crevices.

Analogues of glue b 7000

Glue b 7000 has some analogues with approximately the same technical features. In fact, B6000, B5000, F6000, E6000, E8000, Y7000 and T7000 are characterized by similar properties. Their main difference is the period of setting and complete gluing of spare parts, as well as the level of adhesion.

For example, B6000 adhesive is optimal for working with plastic, fabric and glass. It is characterized by a transparent composition, and immediately after application it begins to harden. It will take approximately eight hours for the composition to dry. It is resistant to mechanical stress and vibration. Even after the substance is completely dry, it will not lose its elasticity.

Another popular touchscreen adhesive in Moscow is B5000. In its principle, it resembles ordinary double-sided tape, but the quality of gluing will be many times better.

If you need to glue a dark surface, you can use the rather unusual T7000 glue. It has a rich black color, so it will be completely invisible on dark surfaces. Its main disadvantage is that it cannot be removed by heating.

We hope you find our article really useful. We wish you success in your work. But before you start, we recommend watching the video instructions on how to glue a touchscreen using b7000 glue with your own hands:

How to glue a touchscreen with glue B-7000

The process of gluing a touchscreen using the B-7000 is significantly reduced compared to other methods and means of repairing touch screens. In addition, B-7000 adhesive increases the reliability of adhesion and the tightness of the entire structure. During the gluing process, you should not rush and not make mistakes, otherwise the risk of dead zones increases or spontaneous touches on the screen appear.

Progress

1. Before installing a new touchscreen, you need to check its serviceability and prepare the seat: remove old tape or glue and degrease it.

2. Applying glue. The main thing here is to maintain a balance - to apply in sufficient and not excessive quantities: so that when applying the glass, the glue does not squeeze out onto the matrix.

3. Peel off the protective film from the inside of the new touchscreen.

4. Install new glass.

5. Connect the power cable, secure it with Kapton tape or tape and assemble the tablet or smartphone.

6. Wipe the glass using light pressure.

7. Check the operation of the device: the touch glass should work across the entire working area, there should be no dead zones or spontaneous touches.

Tip No. 1. If after the glue dries or during repairs the glue leaks out, it can be cleaned with a napkin moistened with gasoline, which dissolves the glue quite well.

Tip No. 2. If the touchscreen is squeezed out of the case after installing it with glue, we recommend using an improvised press or using special clamps with which you can adjust the position of the touchscreen relative to the frame of the case to avoid squeezing the sensor.